Foreign Insulators

by Marilyn Albers

Reprinted from "INSULATORS - Crown Jewels of the Wire", November 1980, page 4

Alice Springs and the Overland Telegraph Line

In last month's

article I touched briefly on the Overland Telegraph Line in Australia, and the

fact that Robert Chiantelli (Monterey California) had found some of the old

porcelain insulators from that line while visiting in Alice Springs. Since then

Mr. N. R. Woodward (Houston, Texas) has supplied me with a trade journal, dated

February 1939, called The Telecommunication Journal of Australia, published by

the Postal Electrical Society of Victoria. In it was this fascinating story

about Alice Springs and the construction of that same Overland Telegraph Line.

Another article called The New Trunk Insulator went on to explain why this

original design of insulator was eventually replaced by one that provided more

insulation resistance. If you have Australian porcelains in your insulator

collection you will probably recognize both of these designs, and after reading

this, you will appreciate them more!

Since the objective of the Postal

Electrical Society is to promote diffusion of knowledge in communication

services, editors are welcome, in fact encouraged, to use any article from the

Journal, provided no more than one third of it is quoted, and proper credit is

given. The articles are well written and easy to read. The parts I left out had

to do with descriptions of the town of Alice Springs, its people, crops and

flowers, trucks getting stuck in mud holes after a good rain, and mail service

by camel! That we can do without!

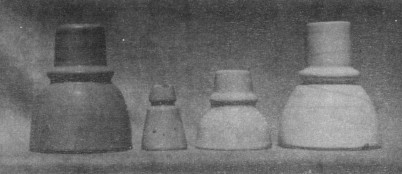

The following pictures show some of the

original old insulators from the Overland Line. In the first two photos we see

some from Robert's collection. Counting slight variations in color (from pure

white to a kind of putty color) and also in measurements, he claims he has found

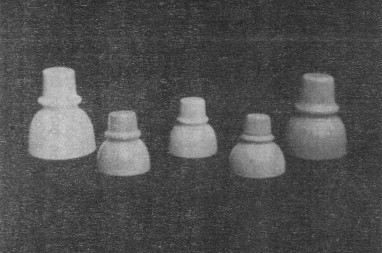

20 different ones. The third photo shows those in my collection, the number

being subject to change after having met Robert at the Bakersfield Show!

Picture

#1

Picture #2.

Picture #3.

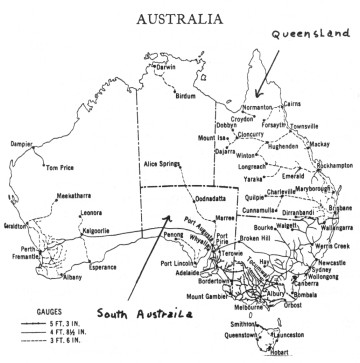

Alice Springs and the Overland Telegraph Line

R. C. M. Dale

The name "Alice Springs" is really a misnomer, because the deep

pool of water after which the place is named is not a "spring" but a

soak. The town, a panorama of which is given below, is in the centre of the

continent on the Overland Telegraph Line between Adelaide and Darwin. The

locality was given its name by a party engaged on the construction of the

Overland Telegraph Line in 1871 when they sighted the big, deep waterhole in the

bed of the dry creek or river now known as the River Todd.

The Todd only flows after each rain, and at this place there is a large

outcrop of granite rocks. The swirling of the quickly flowing water keeps this

big hole washed out and leaves it full of water. Quite good soakage water can be

obtained anywhere in the creek at about six feet down, and this soakage keeps

the hole full of water, and because the hole does not dry out, it was probably

thought by the party that there must be a spring at that place. There are,

however, many springs in the MacDonnell ranges, but none at the particular spot

after which the old Telegraph Station was named.

Although the continent was crossed for the first time by the explorer

(McDouall Stuart) in 1862, less than ten years later a telegraph line had been

completed practically along the route taken by him. In the late 1860's there was

great rivalry between Queensland and South Australia as to who should have the

honour of linking their telegraph system with the cable being laid from

Singapore to Darwin. Each wanted the other Australian colonies to support the

project from their particular point of view. When in June, 1870, no agreement

had been arrived at and the Cable Company seemed to favour the land line being

constructed from Darwin to Brisbane, the South Australian Government, evidently

realizing that some drastic action was necessary if they were to have the line

in their State, made an offer to the Cable Company to build a telegraph line

from Adelaide to Darwin (1975 miles) and have it completed by the time the

Company had completed their cable, this being estimated at eighteen months from

the time of the offer. The offer, which meant that the telegraph line had to be

constructed at the rate of 110 miles per month, was accepted, and heavy

penalties for non-completion of the line in the time were provided for in the

agreement.

Actually it was not until about the middle of August that year that the

construction was commenced. The route was divided into three sections -- from

Port Augusta to latitude 27 deg. S. (about 60 miles north of where Oodnadatta is

now, a distance of 550 miles), from 27 deg. S. to 19 deg. 30 mins. S.

(approximately where the present town of Tennant Creek is, about 570 miles), and

thence to Darwin, approximately 650 miles. The first section was in more or less

settled country and provided very little difficulty, the northern section had

some difficulties but not very great, but the centre section was in practically

unknown country and therefore was the most difficult. Each section was

subdivided into many sub-sections, and a party allotted to construct each

sub-section. A small exploring party went ahead of each main party and marked

out the route to be taken. The equipment of each party included 15 horse wagons,

17 bullock drays, one bullock wagon, five express wagons, 165 horses and 200

bullocks. A depot was established at the Finke River (about 830 miles from

Adelaide) for the provision of fresh meat for the men working on the adjoining

sections, and 2000 sheep were sent there. It must be remembered that all the

material, provisions, etc., had to be hauled from either Port Augusta or Darwin

by horse, bullock vehicle, or camels, and some idea of the difficulties

experienced can be realized by the fact that it took Harvey's party, who

constructed one of the central sub-sections, eight months to reach the beginning

of their section.

It was far too big a job to be done in the time, and when the period had

expired (December, 1871), there were still many gaps in the line. A delay had

also occurred in the cable construction, and although not far off completion,

the cable was not completed on the contracted date. A compromise was reached

regarding the infliction of penalties, which were considerably reduced but not

entirely abolished, and the South Australian Government redoubled its efforts,

but it was not until 22nd August, 1872, that the last gap was closed and

telegraphic communication established between Australia and England. The total

cost of the line was £479,154.

The original line was a 7/14 stranded iron wire conductor, and although most

of it was removed and replaced by a 400 lb. G.I. conductor many years ago, there

are still some small sections of the original wire in use.

During October, 1938, it became necessary to remove a small piece of the

original wire in connection with the establishment of a Telephone Office at

Finke, and it was found that the old wire was in perfect condition and not

showing any signs of deterioration. Several types of insulators appear to have

been used. One type was of porcelain, about 4-1/2 inches across at the bottom,

but having a metal top, two inches in diameter, screwed on to the

porcelain.

Old types of insulators used on the original Overland Telegraph Line

and a piece of the original iron wire. The two outer insulators are the

metal armoured type and the hole. through which the wire was passed can be

seen in the top of the centre insulator. |

A metal plate bolts on to the metal top, and two holes, through which a wire

could be passed were formed when the plate was screwed down. Apparently only one hole was used,

but the tightening of the bolt held the wire firmly between the plate and the

metal top of the insulator. There were thus no tie wires necessary with this

type. Another type is similar to the present day trunk line insulators, a little

smaller, but completely covered with a metal armour. The metal armour is shaped

exactly like the insulator, and the wire was tied to this similarly as is done

on present day porcelain insulators. The porcelain was set into the armour by a kind of

cement, and a thread was provided in the porcelain for the spindle. A number of

these insulators are still to be seen lying along the line, and although over 66

years old, do not show the slightest sign of rust or deterioration.

In many

instances the line did not take a direct route between various points, but followed creeks

and watercourses. The reason for this was that most of the poles

were cut from the timbers growing along these watercourses, and also that it was

necessary to follow them in order to obtain water. However, the white ants soon

showed their presence, and although there are some of the original butts still

to be seen besides the present iron poles, most of the wooden poles had very

short lives, perhaps only of a few years' duration. In 1880, re-poling with

Siemens and Oppenheimer poles was commenced in places, but it was not until

1898, when a 265 lb. copper conductor was added that the line was fully

iron-poled. During the erection of the copper wire and the final iron poles, the

line route was considerably straightened, now following a more direct route

and not keeping to the watercourses. No more wires have been added since then,

but the methods of telegraphy used have kept abreast of the times and enabled

the growing volume of traffic to be handled satisfactorily.

Originally the

messages were repeated by hand at several stations along the route, and in between these stations were many others at which linemen were located. These

latter were placed at points where water could be obtained, and varied in

distance from. 95 to 180 miles apart. As the country became opened up and telegraph systems improved, it became possible to abolish many of these

stations, and one by one they have passed out of the Department's control. Some

are now police stations, some are cattle station homesteads, and others railway

stations. Today the only repeater stations apart from Port Augusta, in the

circuits, are Alice Springs on the copper line, and Marree, Powell Creek and

Alice Springs on the iron. Besides these the only other stations remaining in

the Department's hands are Tennant Creek, Daly Waters and Katherine.

In time,

hand repeating gave way to "pole changer" repeaters, and about 1926 relay

repeaters were installed at

the three repeater stations.

Nearby the pool which the first party had mistaken for springs, the Alice Springs Telegraph Station was built. For many years

it was a lonely outpost, receiving its mail only once every six weeks or two

months. At first it came by packs and camels from Port Augusta, later from Marree,

still later from Oodnadatta, and in 1927 the railway line was completed to

Stuart Town, two miles south of Alice Springs Telegraph Station. Although Stuart Town was surveyed in the late 1890's, it did not

take shape until the completion of the railway. With the growth of the town it

became necessary to establish an official office, and in 1932 the old telegraph

station at Alice Springs was closed and a new post office opened in what was

originally Stuart Town, but which now had its name changed to "Alice

Springs."

It is not often that we get a good downpour of rain, but we

usually manage one good one each year. On 19th February, 1938, from two to five

inches of rain fell from Alice Springs to Oodnadatta. Rivers ran bankers, and at

one time the Alberga was flowing 16 feet above the railway bridge and over half

a mile wide. Communication with Adelaide was completely cut off for several

days, and the train service was not restored until six weeks later. Miles of

railway line was washed away and many sections of the telegraph line carried

away in the floods. Where the telegraph lines cross the Alberga there were two

28 ft. iron beam poles, but after the water had subsided they were found in

different places about a quarter of a mile downstream, one end of each just

showing through the mud and the other end under between six and seven feet of

mud and silt. Some food supplies were brought to Alice Springs by aeroplane, but

by the time the train service had been restored, there were many items which

were unprocurable in the town, despite that rationing had been resorted to.

When

the waters had subsided sufficiently to allow movement, Mr. E. Colson, of Bloods

Creek Telephone Office (the nearest resident to the Alberga River), offered to

attempt repairs to the lines, and set out on camels to do the job. Progress was

slow, as it is a fair day's ride to do 30 miles by camel, especially in wet

country, and stoppages were frequent in order to clear debris away from the

lines. In addition, many detours had to be made to get across creeks and rivers

which were still flowing, and he estimated that to traverse the 100 miles of

line from his place to Oodnadatta, he traveled 160 miles. At the Alberga

crossing he and three natives worked most of one day in water up to their arm-pits, rigging up temporary supports for the line. These were tripods about 10

feet high, and were constructed from timber cut from the trees growing nearby. Insulators were tied on to them, and the lines in turn

tied to the insulators. Altogether it took eight days to travel and repair the

105 miles of line between Bloods Creek and Oodnadatta.

On the south side of the

Alberga no wire was left on the poles (which were washed out and bent all

shapes) for a quarter of a mile, the wire evidently having been caught and

carried away by debris which was washed down. Many miles of railway line and two

bridges were washed away, and it took nearly five months to repair the permanent

way. It is. interesting to note that none of the railway bridges carried away

have been replaced. Instead, the line is laid on a built-in rock foundation in

the bed of the creek or river. Excavations are made to some depth in the river bed and stone or rock firmly packed therein and the

line laid on top of the stone. This method was first tried out when the Finke

bridge carried away about six years ago, and has proved to be quite effective

for, at the most, the damage amounts only to a short length of railway line being

twisted, instead of an irreparable costly bridge.

The New Trunk Insulator

R. M. Osborne, M.E.E, A.M.I.E.E.

With the extension of the practice of dialing over trunk lines, troubles

have been experienced on account of the large variation in the insulation

resistance of the aerial circuits used. Some dialing lines, in wet weather, have

an insulation resistance of 10,000 ohms or even less, and become unworkable, and

in 1936 it was decided that the standard trunk insulator should be re-designed

in order to effect, if possible, an improvement in this state of affairs. It was

recognized that, although there are several sources of loss in a telephone

insulator, by far the most important one at voice and telegraph frequencies is

surface leakage between wire and pin, and the object of the designers was, therefore, to reduce this effect.

With a clean insulator the surface leakage,

even in wet weather, is small, but, as dirt accumulates, a semi-conducting path is

formed on the surface if the atmosphere is moist, particularly if the dirt

includes salt or carbon. The resistance of this path depends upon its length and

cross-sectional area in the same way as the resistance of any conductor depends

upon these variables, and it is therefore desirable to make the length of the

path as great as possible whilst, at the same time, keeping its cross-section

area as small as possible, i.e., by keeping the circumference of the insulator

as small as possible.

This result is partially achieved in many insulators by using two skirts.

The trunk insulator which has been standard in Australia for many years is one

design which incorporates this feature, and so is the B.P.O. trunk insulator.

These two designs are shown in Figs. 1 and 2. Examination of them shows that the

B.P.O. insulator provides a longer leakage path between wire and pin (32 cms. as

compared with 23 cms.), and at the same time the average diameter of the leakage

surface is considerably less (4.60 cms. as compared with 7.54 cms.). Thus, if

each of the insulators has an equal thickness of similar deposit upon it, the

surface resistance of the B.P.O. insulator will be nearly 2.3 times as great as

that of the Australian trunk insulator. In addition, exposure tests conducted at

the Research Laboratories indicated that the external surface of the Australian

insulator which curves outwards is more likely to accumulate dirt than the

straight vertical sides of the B.P.O. design.

It was therefore decided to use

the B.P.O. insulator as the basis for design, but to attempt to make it suitable for use

with wooden spindles which, in Australia, are more economical than steel

spindles. The use of wooden spindles would necessitate increasing the diameter, for it would not be practicable to

obtain a sufficiently strong wooden spindle to fit the thread of the B.P.O.

design.

This increase of diameter would tend to reduce the surface leakage resistance

and also would increase the weight of the insulator; it would therefore be

undesirable. Instead of abandoning the wooden spindle the designers decided to

depart from the B.P.O. practice and eliminate the second skirt. They argued

that, although by doing so they would reduce the length of the leakage path,

they would also reduce the average diameter of the insulator, and thus the two

effects would partly cancel out. Furthermore, they believed that the outer surface, which is continually washed by rain, is the most important part, and that

the elimination of the inner skirt would not be as serious as might be imagined.

To obtain the maximum benefit, however, a wooden spindle of minimum practicable

diameter was designed for use with the new insulator, the final design of which

is shown in Fig. 3. It is hoped that, when tests have been completed, this

insulator will become the Australian Standard Trunk Insulator.

The length of the

surface leakage path of this insulator is slightly less than that of the old

trunk insulator (18 cms. as compared with 23 cms.) but its average diameter is considerably less (5.08 cms. as compared

with 7.54 cms.) and therefore its theoretical surface leakage resistance is greater than that of

the old design. Furthermore, as stated above, a large proportion (57 per cent.)

of its leakage path is exposed to the cleansing action of rain. With the old

trunk insulator, this proportion is 87 per cent. and with the B.P.O. insulator

it is 32 per cent. The designers hope that this feature of the new insulator

will largely compensate for the higher theoretical leakage resistance of the

B.P.O. insulator.

After the design had been completed, it was decided to conduct

field tests by installing the insulators on the Melbourne-Geelong trunk route

but, before this was done, the decision to scrap this route made other plans

necessary, and it was decided to equip certain lines between Melbourne and

Dromana which were known to have very low insulation resistance during periods

of high humidity. It was. intended to equip one circuit with the new insulators

made of porcelain, and one circuit with B.P.O. porcelain insulators, and to

compare the results obtained with the standard Australian porcelain insulators

erected on the same poles. It was then thought advisable to make some of the new

insulators in glass in order that the value of this material for the purpose

could be examined. The Australian Glass Go. agreed to co-operate but pointed out

that the new design, although suitable for porcelain, was not ideal for glass

because of the cooling stresses likely to be set up in the body of the

insulator. They submitted a design which gave the same leakage path but which,

they considered, would be better for glass, and the Department purchased

sufficient of these insulators to equip a circuit between Melbourne and Dromana.

Fig. 4 shows a glass insulator of the design tested.

[At the time these tests were being made (1936) Australian Glass Company's

insulators would be marked Agee (AGEE). I don't recall seeing any insulators so

marked with this design. It is not a CD 130.7, though similar. Maybe it was discarded, and later evolved into the 130.7 we all know, and marked A.G.M.

M.A.]

The installation of the insulators on the Melbourne-Dromana circuits was completed in March, 1938, and each of the

circuits was connected to the Research Laboratories by an underground cable

pair between the Glenhuntly cable head at the Melbourne end of the circuits,

and the Laboratories, and a recording galvanometer was arranged to record the

insulation resistance of each of the circuits. The method of connection did not

affect the usefulness of the circuits for their normal traffic, and they were not, therefore, withdrawn

from service. Before tests commenced, the insulators on these lines were cleaned

by spraying them from the ground.

In July, 1938, the first analysis of the

results was made. As was known, the insulation of the various lines varied

considerably with the humidity, and in order to compare the results, it was

therefore necessary to compare the readings at equal humidities, and for the

purpose of these tests, the readings at high humidities are, of course, the most

important because it is under these conditions that lowest insulations occur.

Some variations occurred in the day by day readings, but the lowest insulation

resistances recorded at any time were as under: --

B.P.O. Standard

|

38,000 ohms.

|

Australian Single Skirt--

|

|

Porcelain

|

34,000 ohms.

|

Glass

|

14,000 ohms.

|

Australian

Double Skirt (old design)

|

5,000 ohms.

|

These readings are the overall readings

between wires of the lines which are approximately 46 miles long; the lowest

readings at other humidities were in about the same order. For example, at 80

per cent. they were:--

B.P.O. Standard

|

450,000

|

Australian Single Skirt--

|

|

Porcelain

|

450,000

|

Glass

|

160,000

|

Australian Double Skirt (old de sign)

|

50,000

|

These results

are very satisfactory and, so far, confirm the designers' belief in the single

skirt design. It would be unwise to be unduly optimistic until further results

have been obtained and the effect of weathering has been ascertained, but on the

results so far, the Department has felt justified in purchasing large supplies

of trunk insulators to the new design. This will, of course, introduce

complications such as are always met when an old standard is replaced by a

new, but it is felt that the advantages to be obtained are very real and far

outweigh the objections.

The reason for the low value of the glass insulator is not very clear at

present, but it is possibly due to the presence of cracked insulators on the

line. During installation, some of these insulators cracked and a number actually

broke. Whatever the reason, however, the results so far reflect some

inferiority of the glass insulators installed for test, which may or may not

become more pronounced as the tests proceed.

It is possible that an extra groove may be added to the design of Fig. 3, but

unless future tests cause opinions to be modified considerably, it is probable

that no drastic alterations to it will be made and that it will become the new

Departmental Standard, and will be known as Insulator, Trunk, L.S. (Long Skirt)

to distinguish it from the present Trunk Insulator. The new wooden spindle for

use with it has already been designed, and designs for the necessary steel

spindles are in course of preparation.

- - - - - - - - - -

Many thanks to Mr. Woodward for sharing this information with us!

|